【晶體成長】

Crystals grown by image furnace

(Traveling Solvent Floating Zone method)

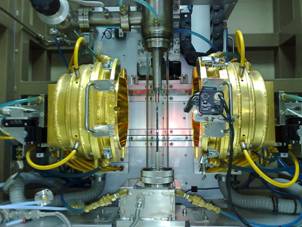

The technique we are using is the so called Traveling Solvent Floating Zone (TSFZ) method. The major advantage of this technique is that crystals can be grown without getting into touch with other materials, such as crucibles, which eliminates a major source for contaminations. An infrared radiation furnace (model SC-15HD, NEC Nichiden Machinery) equipped with two ellipsoidal mirrors and two 1.5 kW halogen lamps positioned at the f°Ci of the mirrors were applied in our lab. A picture of this furnace is displayed in Figure_1. With two halogen lamps (max 2×1500 W), this furnace can work at a temperature up to 2000 °C. Crystals with high melting point as well as a large length can be grown. The latter is particularly important in the case of incongruent melting systems, where large deviations between the nominal composition and that of the grown crystal are observed in the beginning of the growth experiment. Feed rod, melt and crystal are l°Cated within a sealed quartz tube, which allows performing crystal growth in different atmospheres.

The technique we are using is the so called Traveling Solvent Floating Zone (TSFZ) method. The major advantage of this technique is that crystals can be grown without getting into touch with other materials, such as crucibles, which eliminates a major source for contaminations. An infrared radiation furnace (model SC-15HD, NEC Nichiden Machinery) equipped with two ellipsoidal mirrors and two 1.5 kW halogen lamps positioned at the f°Ci of the mirrors were applied in our lab. A picture of this furnace is displayed in Figure_1. With two halogen lamps (max 2×1500 W), this furnace can work at a temperature up to 2000 °C. Crystals with high melting point as well as a large length can be grown. The latter is particularly important in the case of incongruent melting systems, where large deviations between the nominal composition and that of the grown crystal are observed in the beginning of the growth experiment. Feed rod, melt and crystal are l°Cated within a sealed quartz tube, which allows performing crystal growth in different atmospheres.

Figure_1 Apparatus of the Floating Zone crystallization method. |

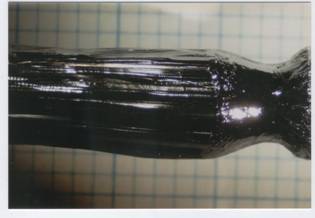

Figure_2 A typical photograph of as-grown Bi2Sr2CaCu2Oy crystal boule. |

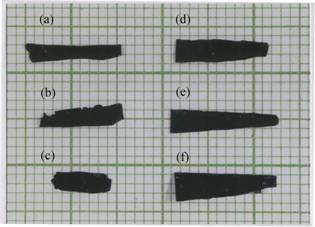

Figure_3 A photograph of Bi2Sr2RCu2Oy single crystals, where R represents Ca, Pr or Gd. Crystal (a) and crystal (b) are as-grown Bi2Sr2CaCu2Oy single crystals, and crystal (c) is Bi2Sr2GdCu2Oy single crystal. Crystals from (d) to (f) are Bi2Sr2PrCu2Oy single crystals. The actual size of a square in the background is 1 × 1 mm2.