A. Ultrasonic Bath:

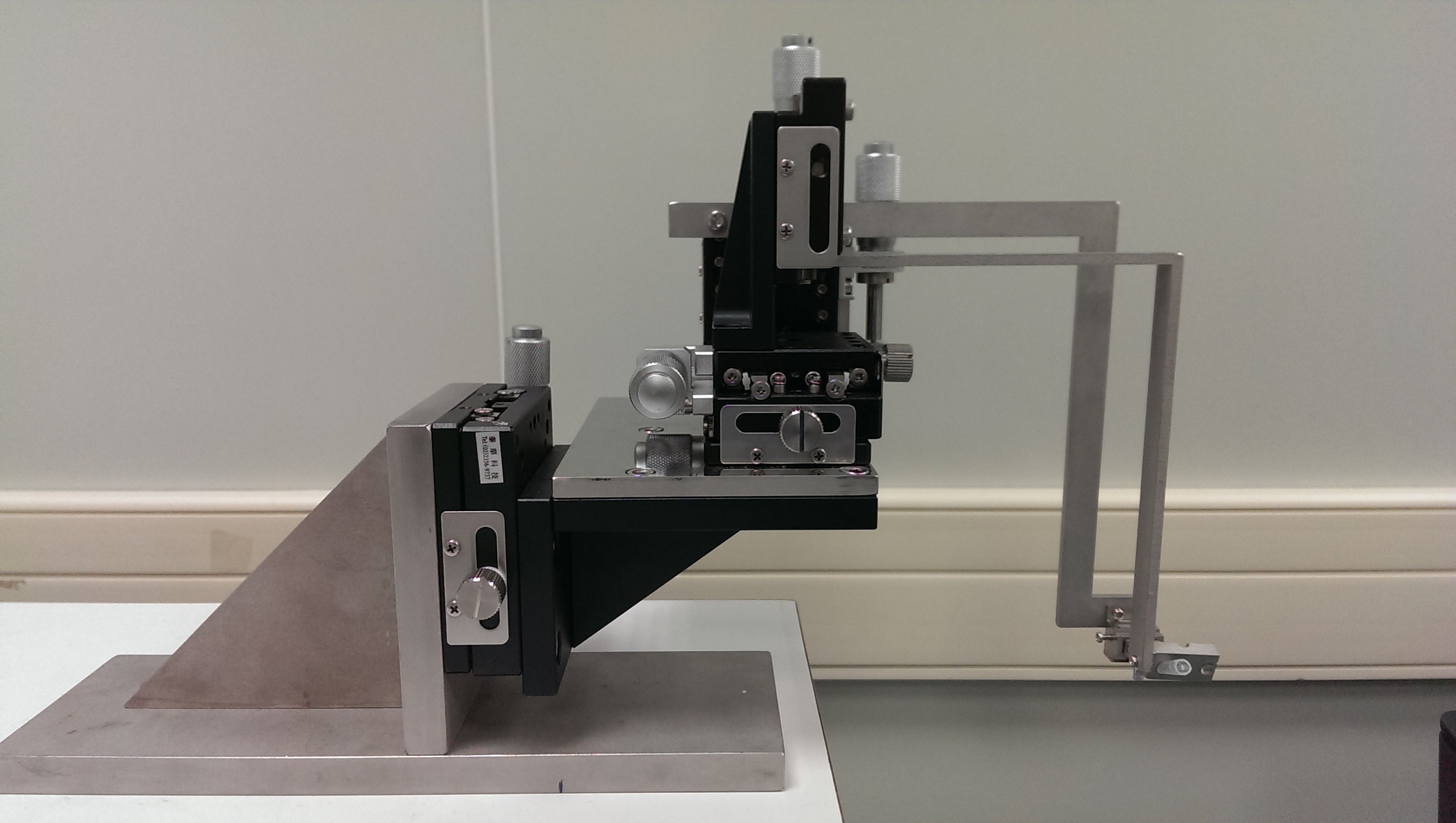

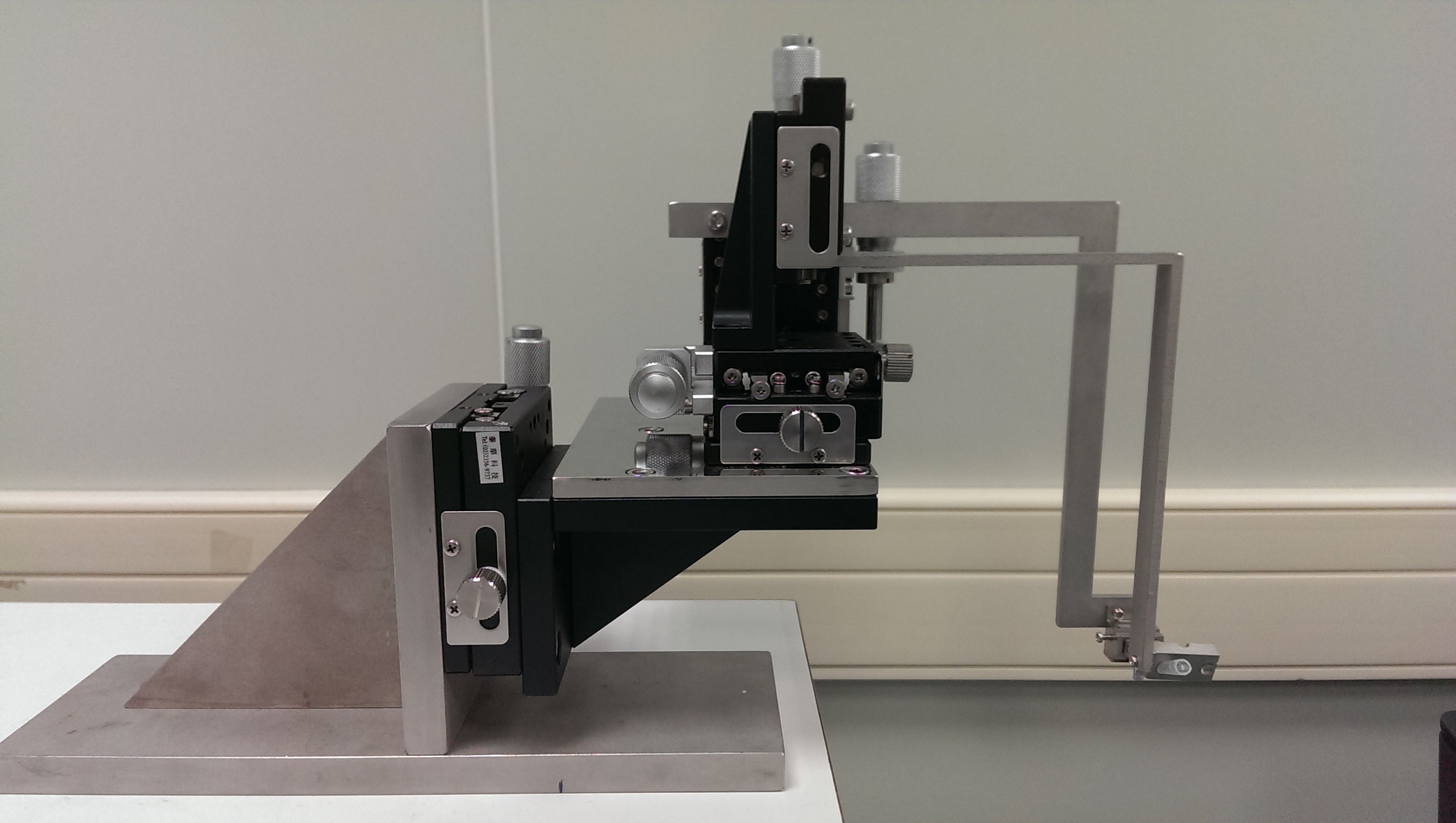

B. Apparatus:

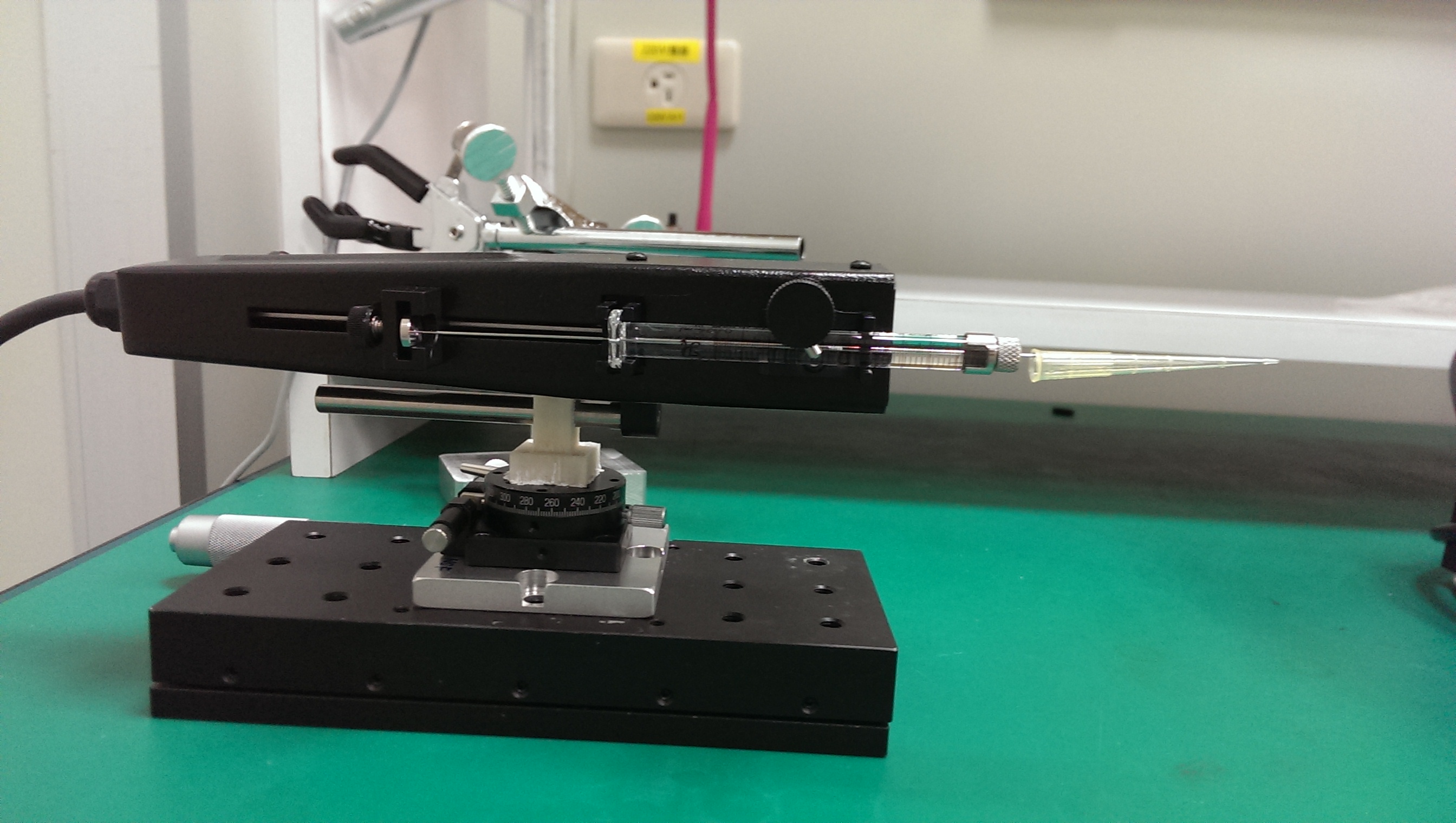

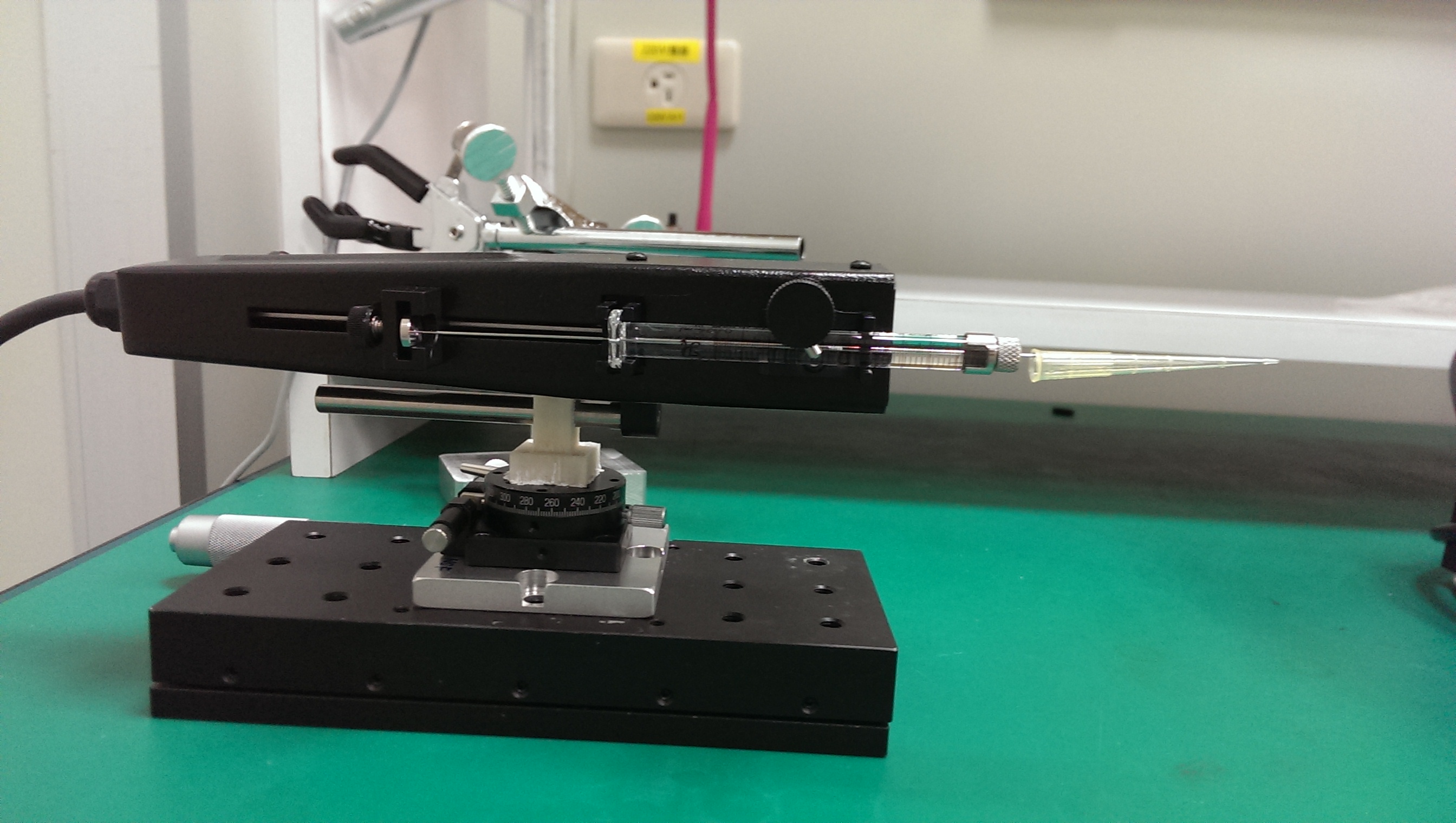

C. Syringe Pump:

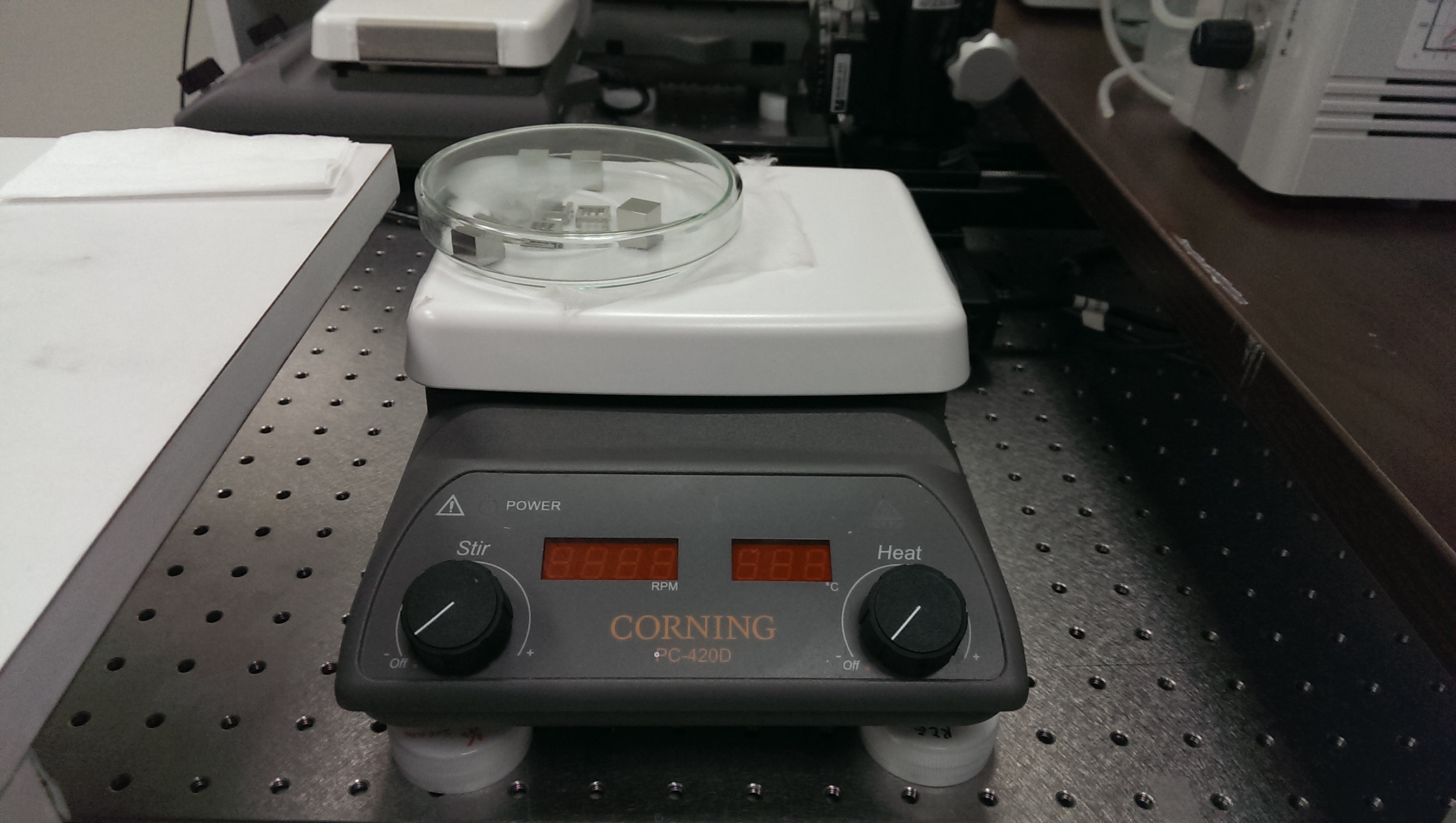

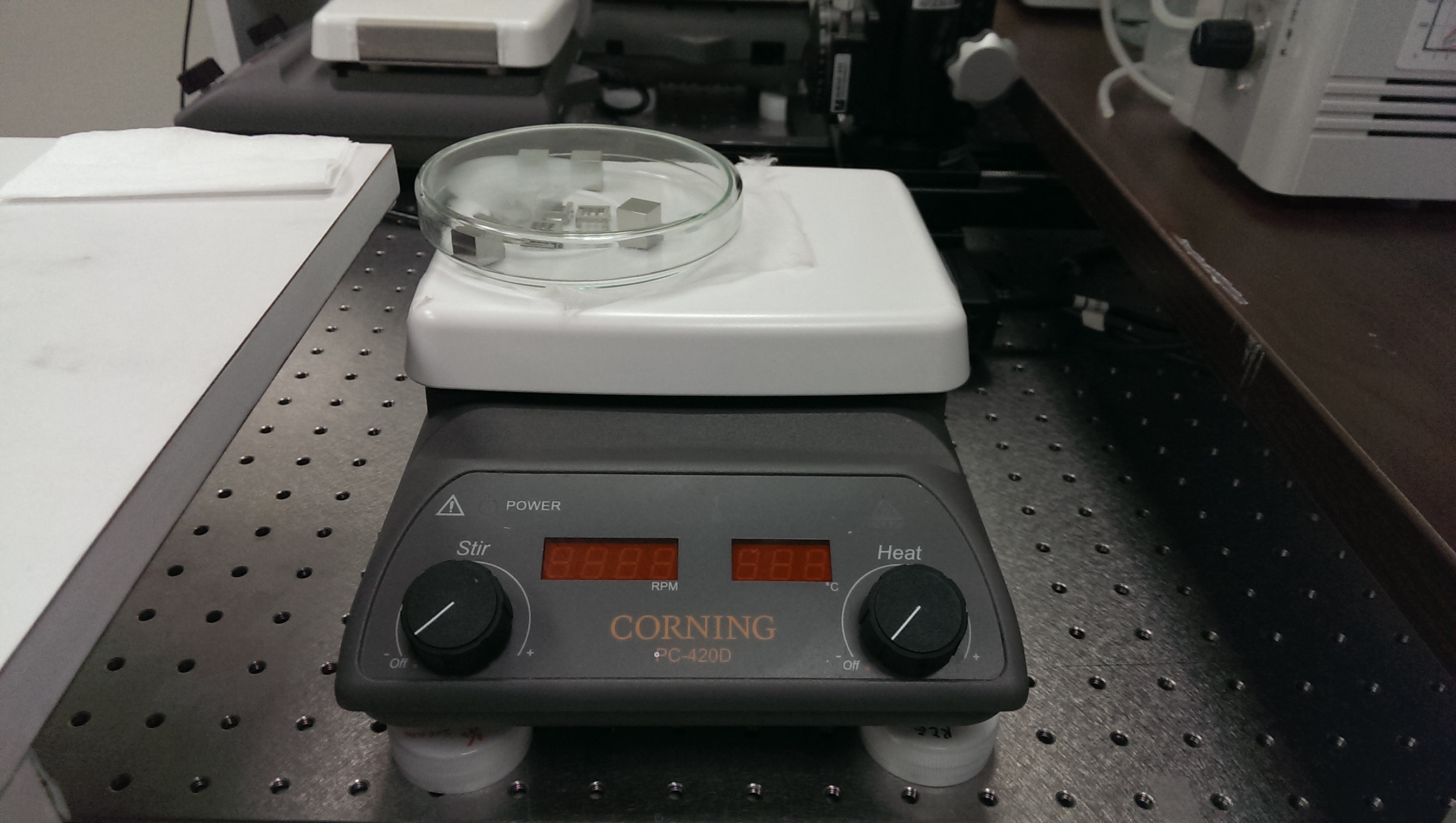

D. Hot Plate:

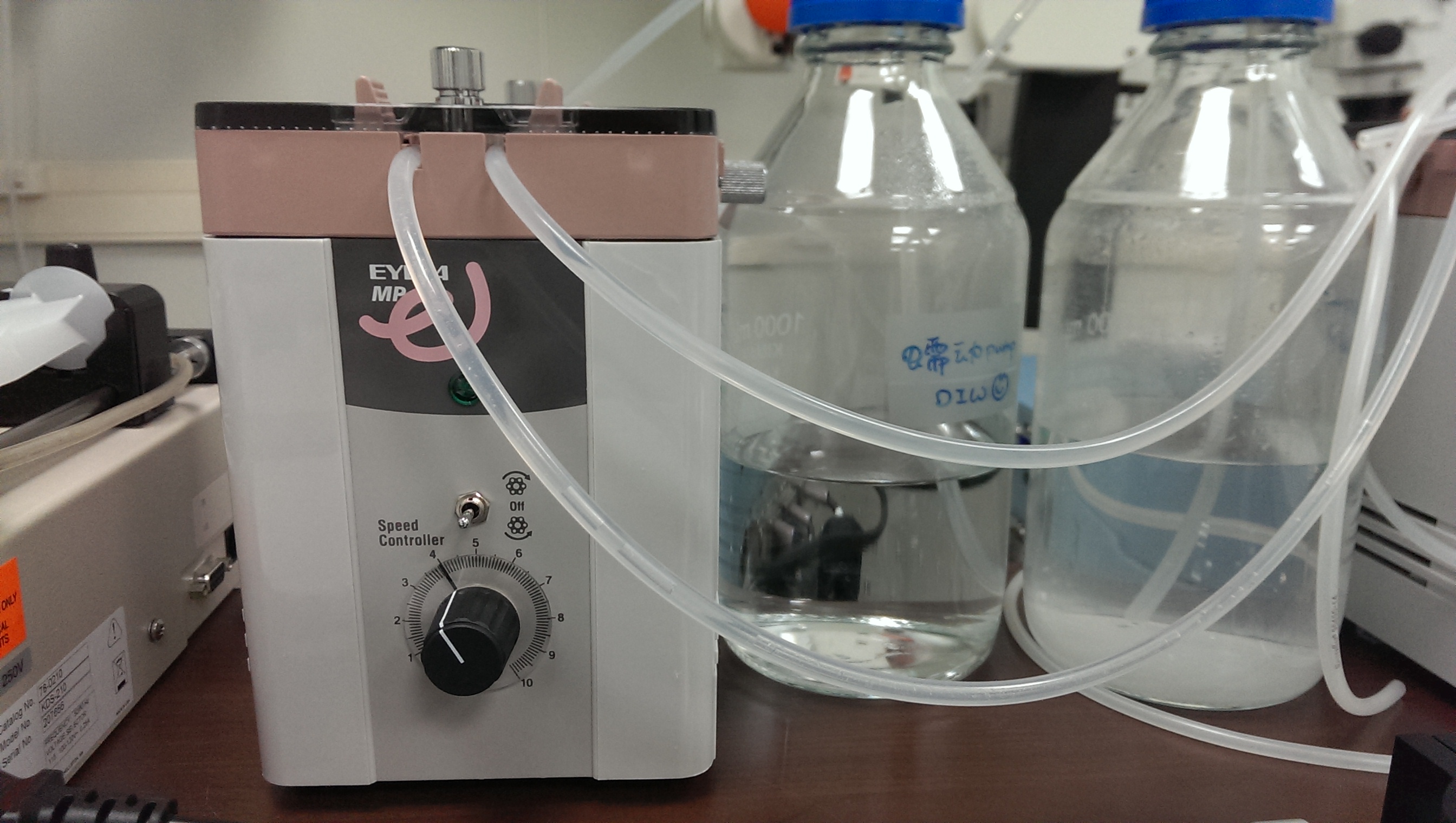

E. Water Pump:

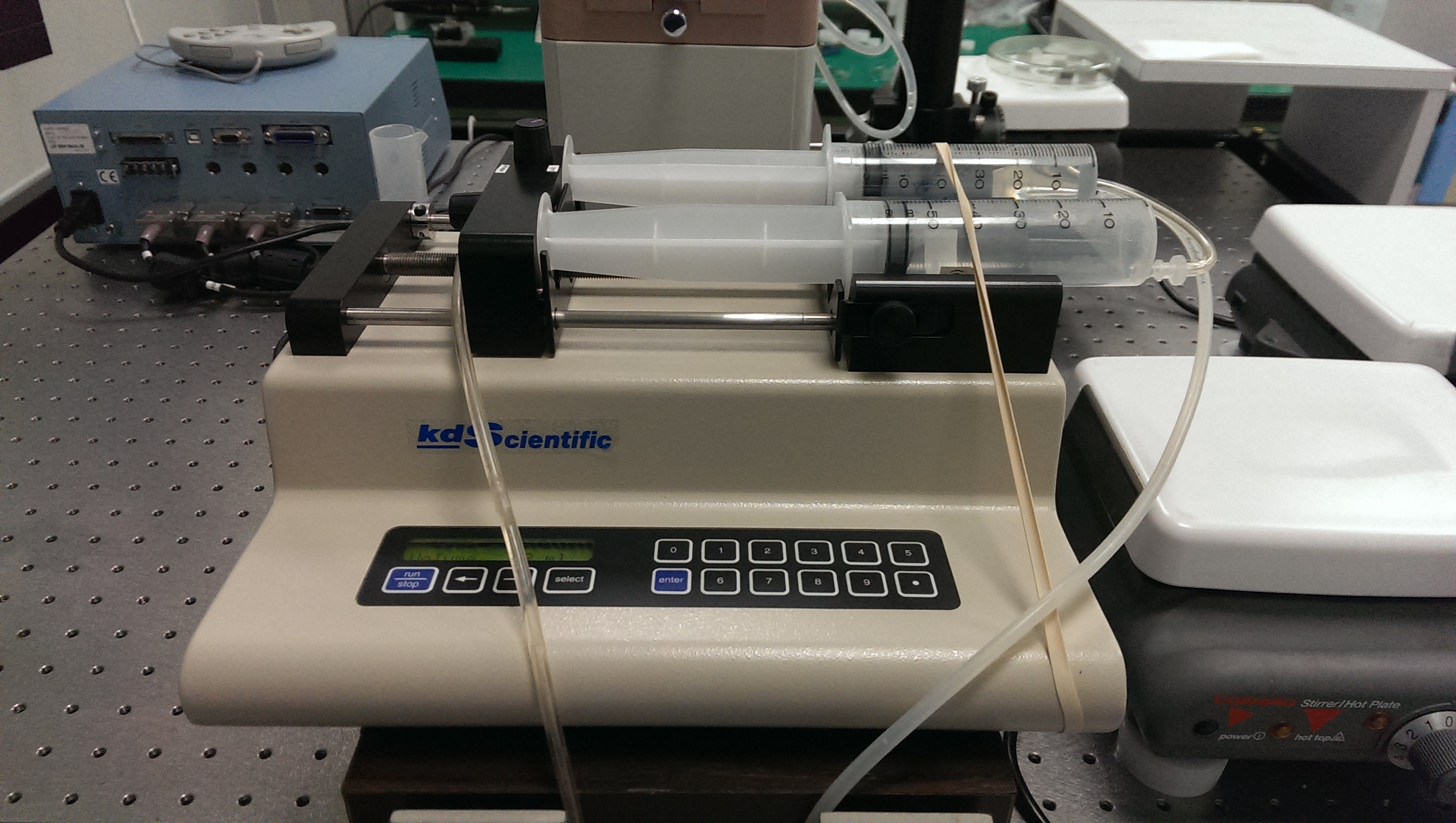

F. Double Syringe Pump:

By P.Y. Chen

中文版5. Removing/Refilling the Water

Equipment (Top)

|

A. Ultrasonic Bath:

|

B. Apparatus:

|

|

C. Syringe Pump:

|

D. Hot Plate:

|

|

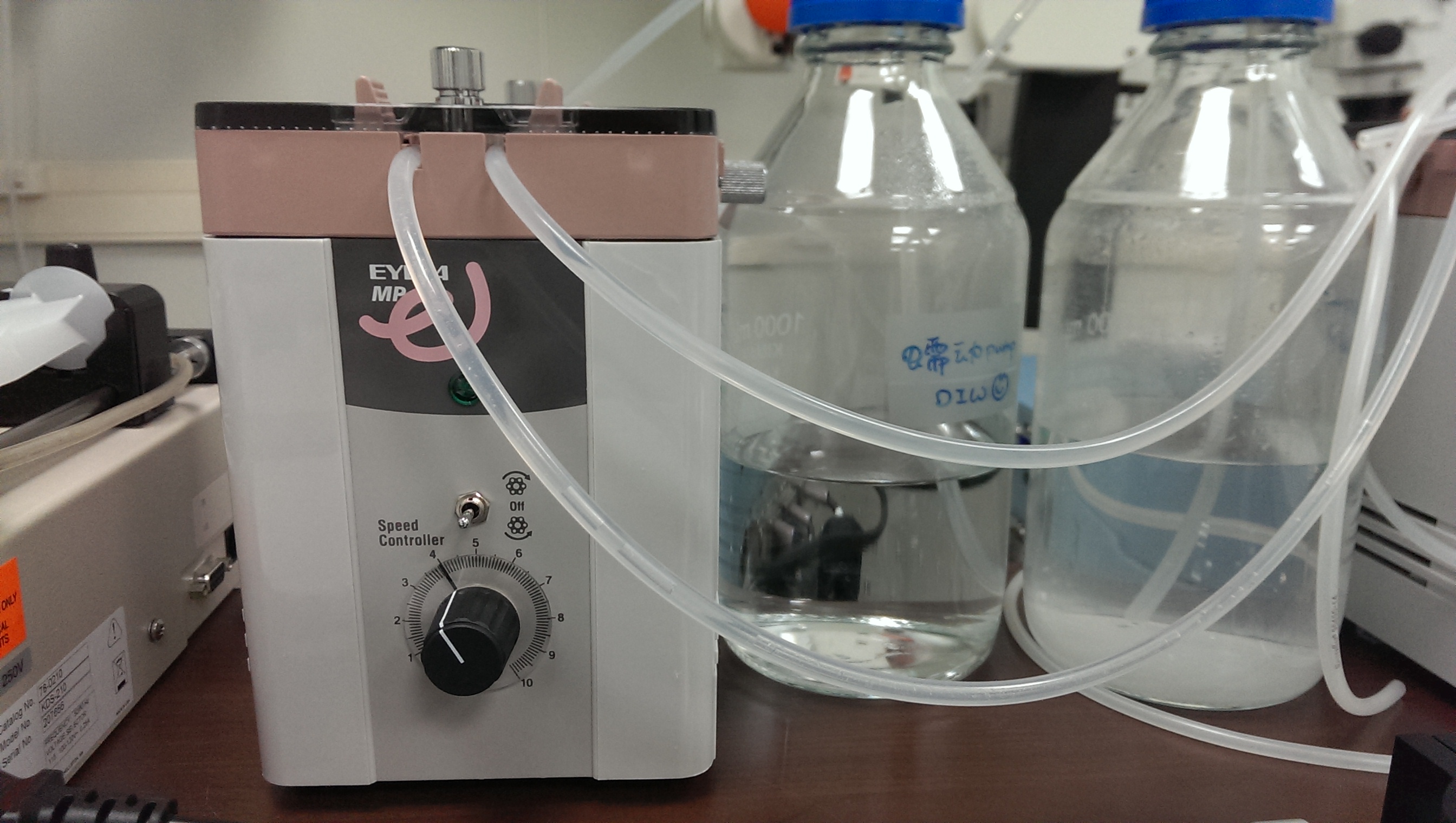

E. Water Pump:

|

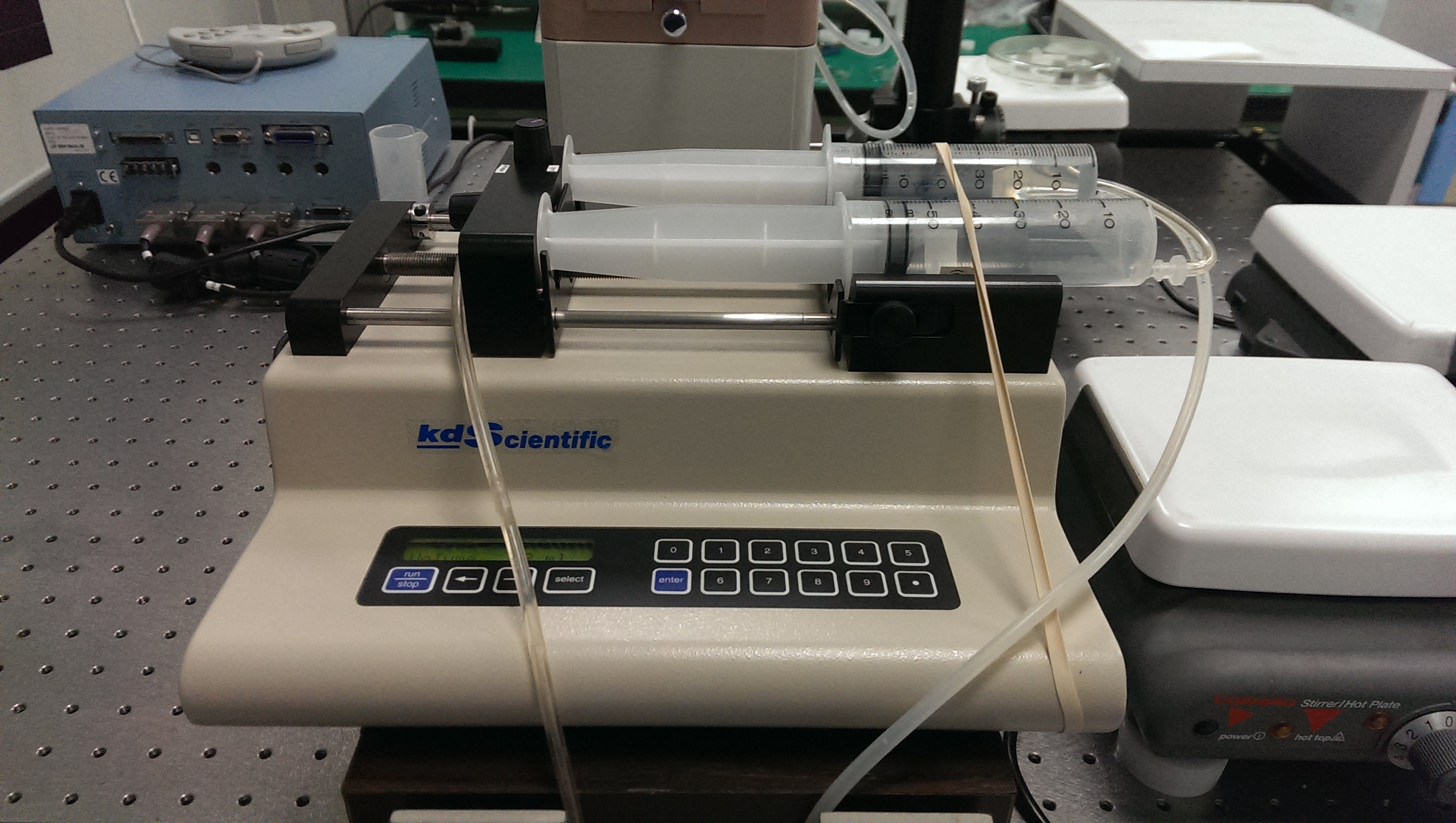

F. Double Syringe Pump:

|

1. Cleaning Materials (Top)

1. Sonicate (A) all materials in "City Water" for 10 min. Dump out the water and replenish. Repeat for a total of 3 sonications.

2. Repeat step (1) using DI Water instead of "City Water."

3. Dry all materials. Then treat with O2 plasma for 15 min.

Materials: petri dish, teflon ring, metal cubes, wafer racks, magnetic stir bar.

2. Preparing NS Solution (Top)

1. Add the required amount of stock solution to a centrigue tube. (1 wt% stock sol'n has a pointed cap; 10 wt% stock wol'n has a flat cap) Centrifuge for 12 min. at 12.5 krpm.

2. Remove the supernatant and add 0.5 mL of DI water. Vortex to mix well and centrifuge again. Repeat for a total of 3 times.

3. Remove the supernatant and add the appropriate amounts of DI water, SLS, and EtOH (according to the table below).

| NS Diameter | NS 1wt% Stock Sol'n (mL) | EtOH (μL) | 18.2MΩ DI Water (μL) |

| 200 nm | 0.5 | 25 | 25 |

| 300 nm | 0.5 | 25 | 25 |

| 400 nm | 0.5 | 25 | 25 |

| 500 nm | 0.6 | 25 | 25 |

| 1000 nm | 1.0 | 25 | 25 |

3. Preparing the Apparatus (Top)

1. Sonicate (A) the prepared NS solution for 10 min.

2. Arrange all materials within the petri dish.

3. Place the dish on a hot plate (D) and stir at 60 rpm.

4. Add DI water to the outside of the teflon ring.

5. Suction the surface water within the teflon ring. When the water level has lowered, replenish by pouring DI water to the outside of the ring. Repeat for a total of 3 times.

6. Secure the guiding plate to the apparatus and position it such that the board touches the surgace of the water within the teflon ring.

7. Sonicate the guiding pipette tip and secure it to the apparatus (B).

8. Cut off an appropriate length of thin tubing and secure one end to the syringe pump (C).

9. Withdraw approximately 20μL of the prepared NS solution. Position the free end of the tube such that it is supported by the guiding pipette tip and that it just barely touches the guiding board.

4. NS Coating (Top)

1. Turn on the syringe pump (C) and infuse at a rate of 0.4 μL/min.

2. When liquid emerges from the tube, move the tube such that it touches the guiding plate, allowing the solution to flow down onto the water surface.

3. Observe the water surface. Once the teflon ring is completely filled with NS's, stop the syringe pump. Remove the guiding plate from the water surface.

4. Cover the plate with a lid to prevent contact with dust.

5. Removing/Refilling the Water (Top)

1. Turn on the water pump machine (E) and rid the tubes of any bubbles. (Power on by pushing down on the toggle)

2. Carefully secure the ends of the tubes into the dish lid such that they are submerged.

3. Adjust the speed to "4" and allow to pump for 2-3 hours.

6. Adding PEO (Top)

1. Using a pipette, add 50 μL of 0.25 wt % PEO to the outside of the teflon ring.

2. Cover the dish with a lid and allow to sit overnight.

3. Repeat step 5 to remove the excess PEO in the DI water before going on to the next step.

7. Removing the Water (Top)

1. Secure the tubes of the double syringe (E) into the dish lid such that they are submerged. Set the rate to 10 mL/min and the volume to 60 mL. Turn on the pump and suction out the water. Turn it off once the water level is below the wafers.

2. Open the lid such that it is ajar and allow to air-dry for at least 3 hours.

3. Heat up the hot plate (D) to about 50-60 C to speed up the substrate drying process.