Yuan-Chih Chang, Yuan-Hong Liaw, Yang-Shan Huang,Tung Hsu, *Chia-Seng Chang, and Tien-Tzou Tsong

Institute of Physics

Small 4:2195-2198 (2008)

Multi-walled carbon nanotubes are manipulated in-situ using an UHV TEM/ STM method. This method allows for the ‘‘peeling’’ of internal layers of the nanotube, producing low-mass, high-diameter nanotubes, suitable for application as nanoparticle probes, or as nanobalances. The precision of the technique is such that it is possible to reinsert the peeling layers, forming a cylinder/piston-type.

Multi-walled carbon nanotubes are manipulated in-situ using an UHV TEM/ STM method. This method allows for the ‘‘peeling’’ of internal layers of the nanotube, producing low-mass, high-diameter nanotubes, suitable for application as nanoparticle probes, or as nanobalances. The precision of the technique is such that it is possible to reinsert the peeling layers, forming a cylinder/piston-type.

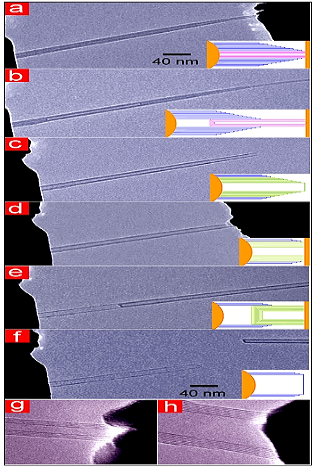

The benefits of our combined TEM/STM approach in this study include real-time measurements, increased resolution, and sequential operations. An extracted inner tube can be reinserted into its original casing and moved along the axis of the tube like a piston rod in a cylinder ring, as shown in Figure 1. In order to achieve this, the positions of the rod and ring were adjusted to almost the same level, within a few angstroms, using the standard focus determination rule of TEM.

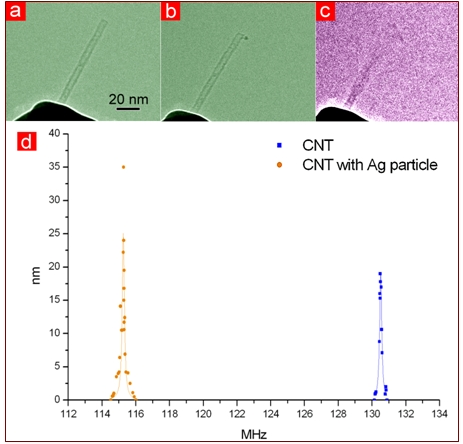

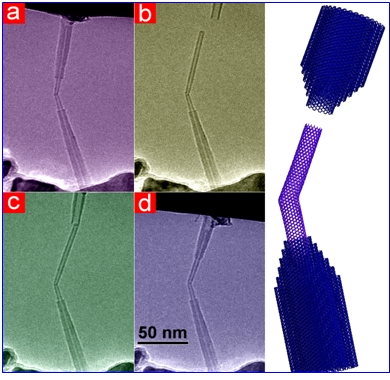

Figure 2 displays TEM images of a MWNT at different stages in successive inner peeling processes. When the gold knife edge was pulled away, the attached inner tubes were extracted from the MWNT. Figure 2b shows inner tubes pulled halfway out of the outer tubes. A clean area of the knife-edge was moved to the tip of the MWNT and the same process was repeated to pull out more inner layers, as shown in Figure 2d and e. A small Ag particle of about 3 nm in diameter was attached to its top end. The resonance frequency of the original tube was 130.5MHz, and was shifted to 115.3MHz after the attachment of the particle. By simple calculation using a previously described formula, the mass of the Ag particle was estimated to be 1.8*10-19 g, which is close to the mass of 1000 atoms, roughly a 3 nm Ag particle. Based on the shape of the curve in Figure 5d, it exhibited a very high Q factor (1000). The ultimate mass resolution is determined by this factor and, for the current tube, the mass sensitivity is about 10-22 g.